Welcome to ZUNDAR, where industry experience and reliability converge to provide cutting-edge environmental testing solutions. With a rich history that began in 2000, we have steadily grown into Shanghai Zundar Technology Co., Ltd. Throughout the years, we have achieved numerous milestones that define our commitment to excellence and reliability.

Warehouse and Material Area

Warehouse and Material Area

Sheet Metal Processing

Sheet Metal Processing

Welding Area

Welding Area

Equipment Assembly Area

Equipment Assembly Area

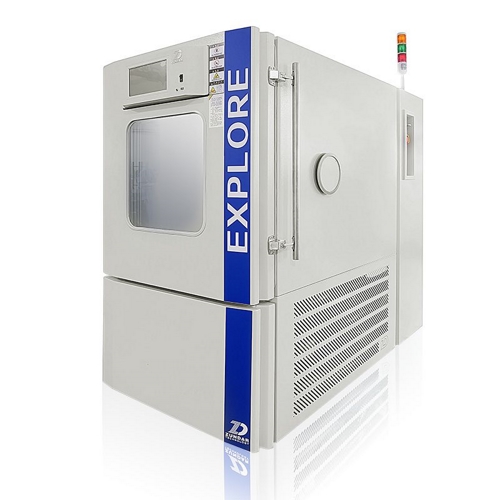

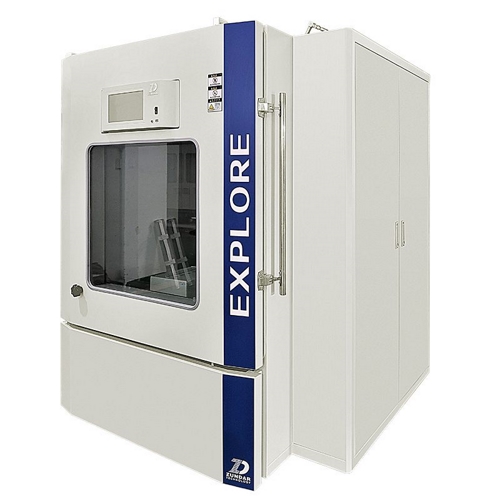

Temperature & Humidity Test Chamber

Temperature & Humidity Test Chamber

Rain Test Chamber

Rain Test Chamber

Battery Test Chamber

Battery Test Chamber

Climate Test Chamber with MAST Table

Climate Test Chamber with MAST Table